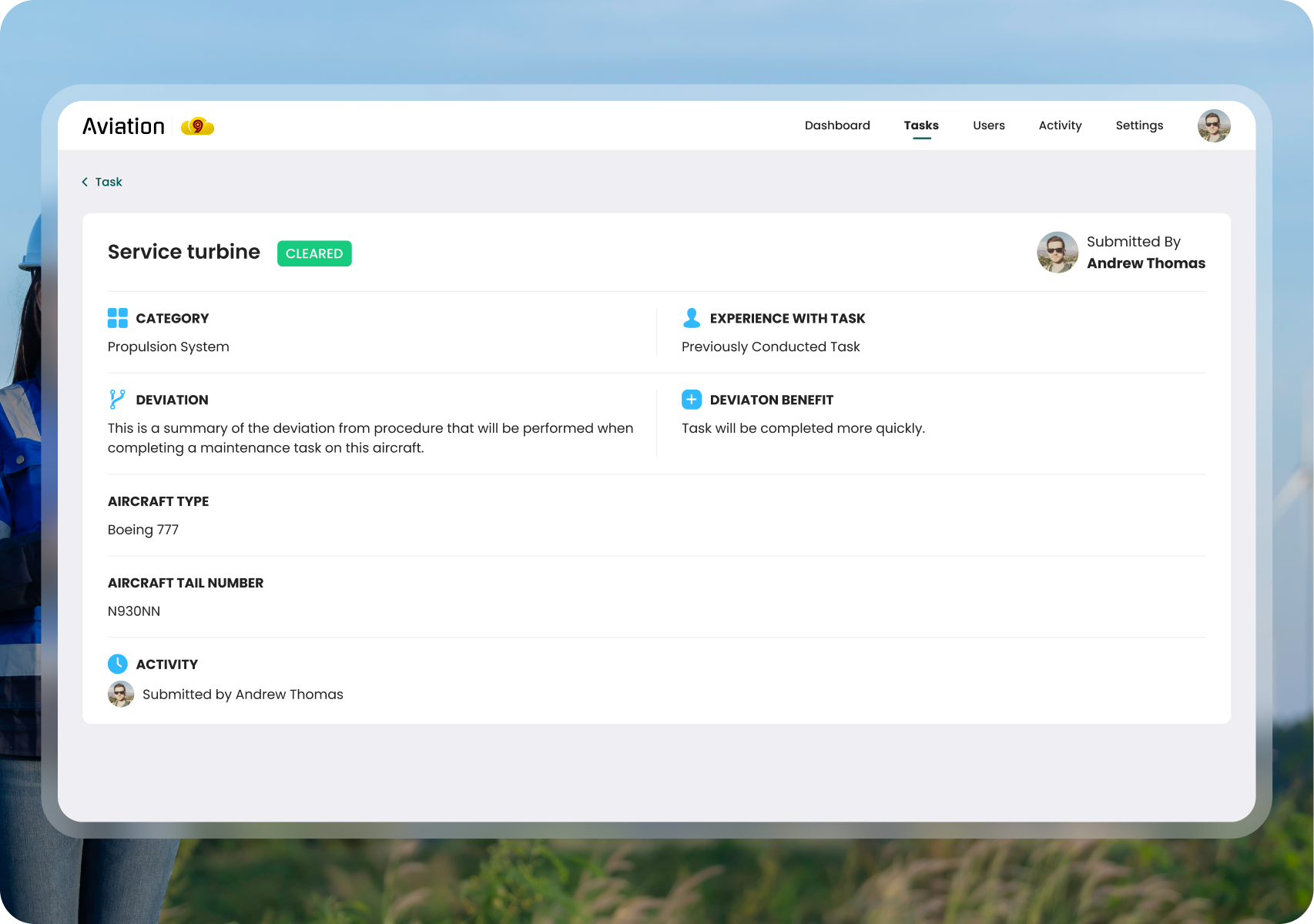

The Aviation Software simplifies aircraft maintenance processes with tracking work, logging discrepancies and monitoring component status such as propulsion systems. And with capabilities such as deviation benefits and task experience tracking, it aids in faster, more accurate maintenance decisions for the Boeing 777.

Community Engagement Solutions

The Challenges

Building a reliable aviation maintenance system came with several critical technical and operational hurdles:

Decentralised Logs

Previously, maintenance records were scattered between paper checklists, emails and older tools which would create inefficiency in following the history of tasks and finding deviations between processes.

No Task-Level Visibility

Technicians didn’t have the ability to see real-time actual status of tasks, which caused technician type delays for approvals and miscommunications between teams as well as different reports between aircraft servicing processes.

Inconsistent Workflows

Variation from different teams performed task servicing by experience rather than standardized practice which could produce variation, error and delays in maintenance.

Complex Aviation Compliance

With aviation grade safety and logging requirements precise data mapping and rigorous documentation protocols were forcing integration with legacy systems to remain extremely challenging.

The Solutions

To address this challenges, EncodeDots built an aviation maintenance application that offers:

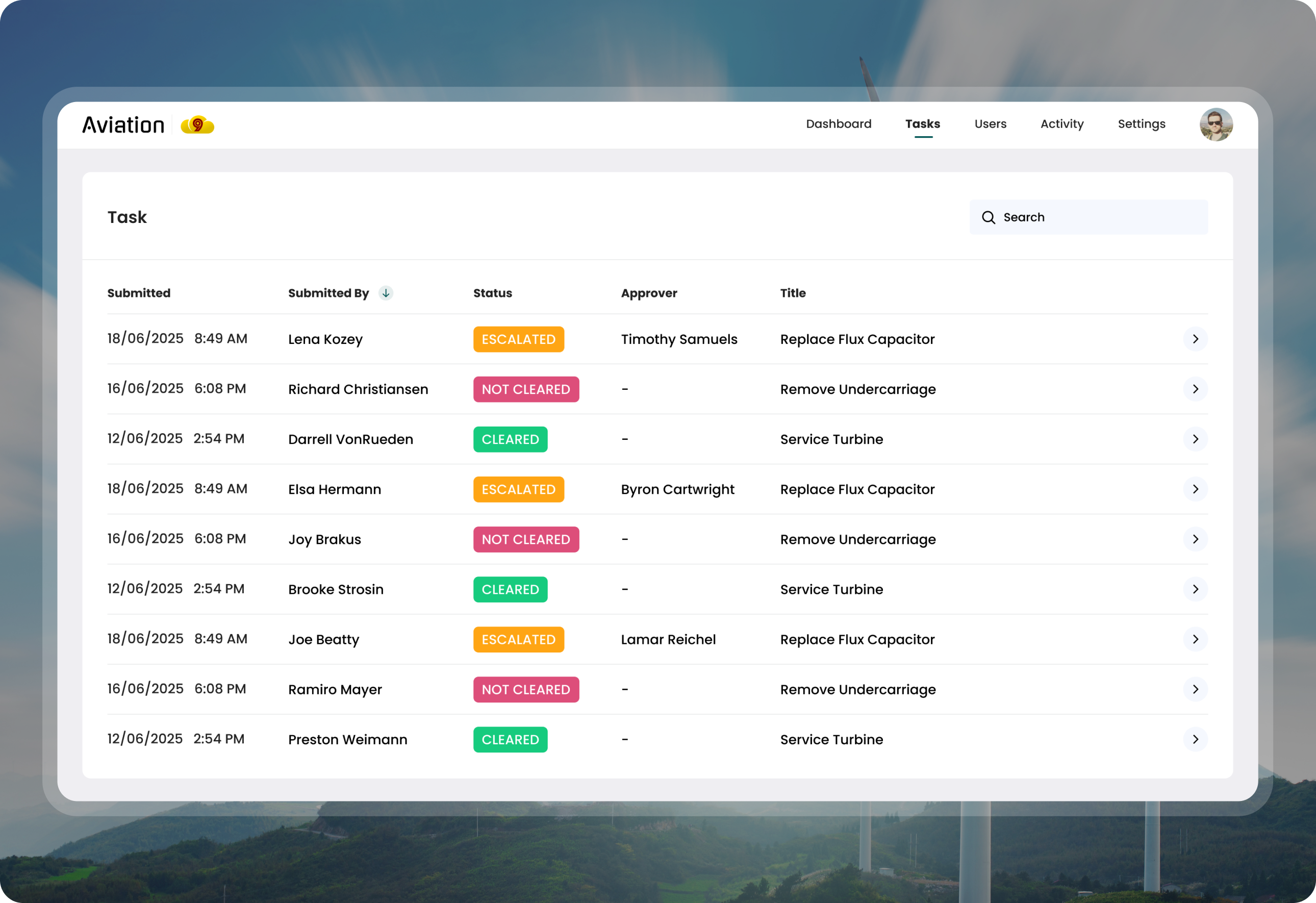

Centralised Task Hub

We built an integrated system that everyone can enter, track and update maintenance tasks on in real-time so there’s no lost tasks between teams or aircraft.

Deviation Logging & Control

Story Developed deviation management enables the team to record wherever the system didn’t follow the prescribed path with the explanation and the value of recording this alternative process for easier audit preparation and regulatory transparency.

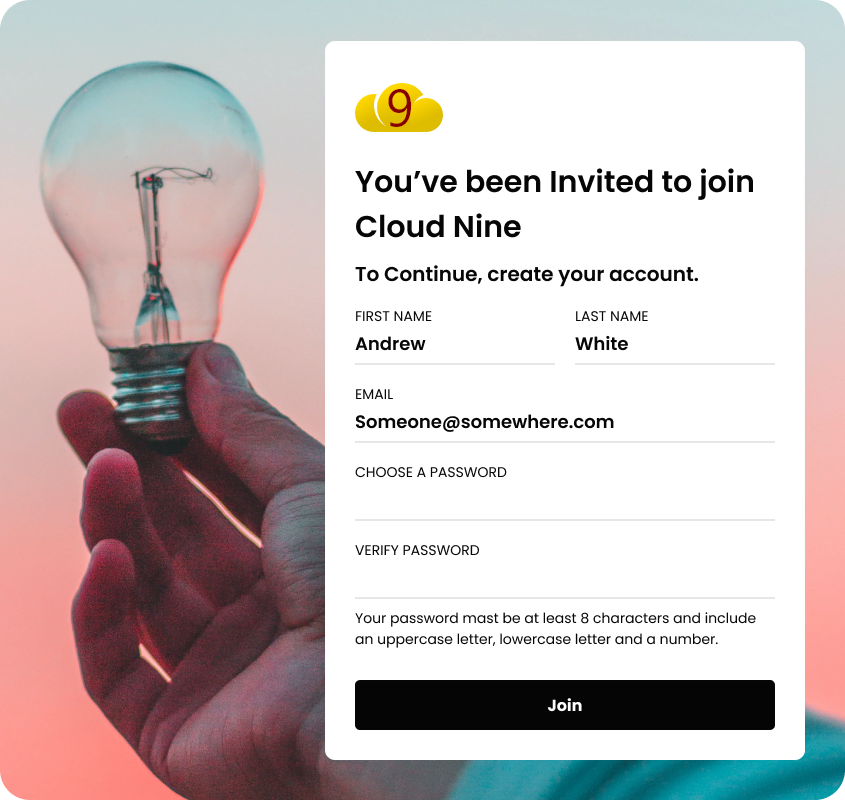

Role-Based Workflow

Role-based access was built where techs, engineers, and supervisors could see and take actions their role could allow to approve, reducing noise on interface.

Aircraft-Specific Intelligence

The solution manages aircraft specific data, including models and tail numbers, and the availability of this data is critical for work order management and maintenance cycle reductions thanks to smart task recommendations.

Strategic Digital Solutions That Deliver Measurable Impact

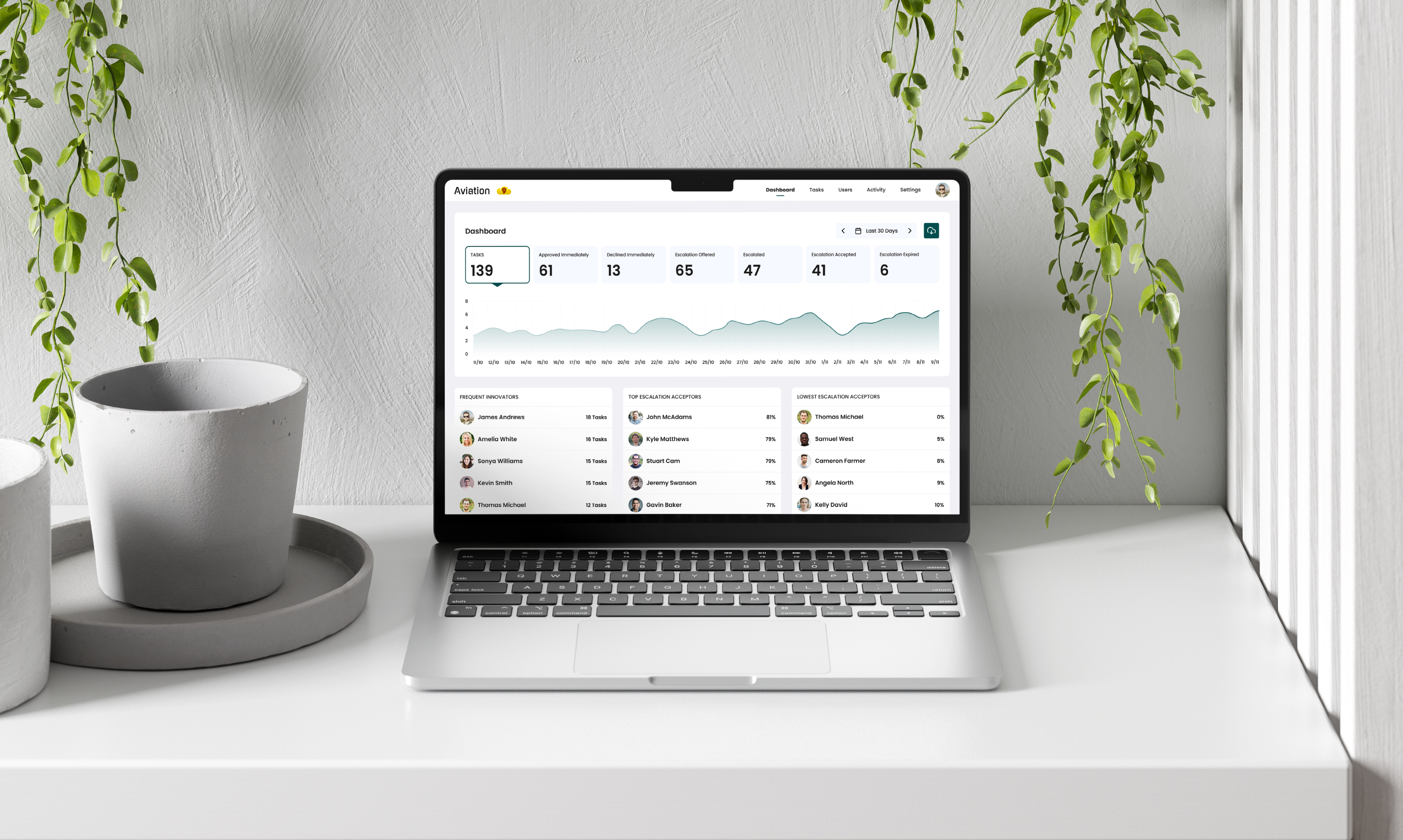

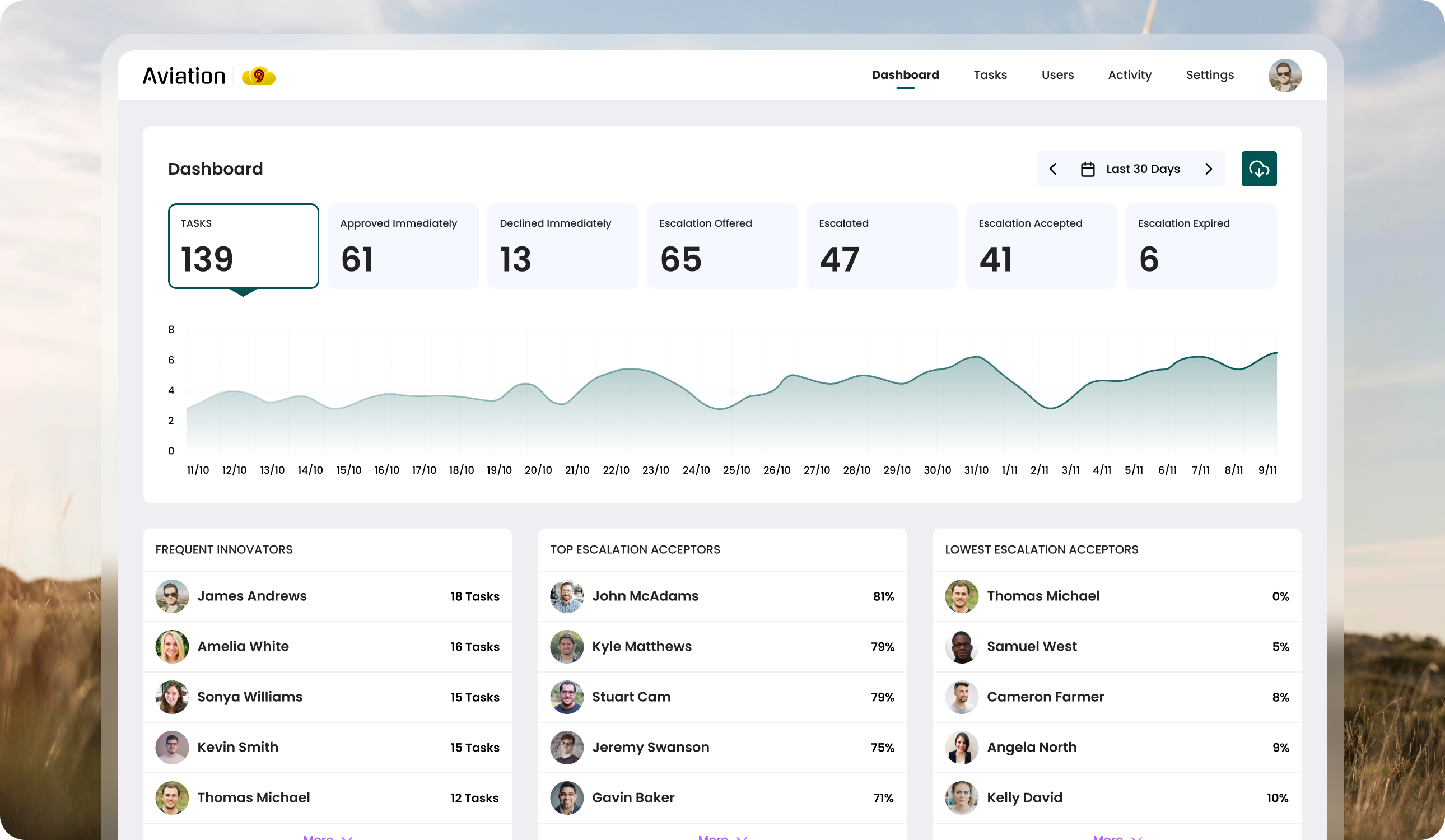

Improved Task Efficiency

Technicians completed maintenance procedures faster by accessing a centralised dashboard and pre-filled task histories, reducing downtime and minimising back-and-forth communications.

Enhanced Compliance

With built-in deviation tracking and aircraft-specific logs, the system ensured all records were audit-ready and aligned with aviation safety regulations and standards.

Seamless Collaboration

Role-based access enabled smoother coordination between engineers, supervisors, and inspectors, allowing for quicker approvals and real-time updates across the maintenance process.

Real-Time Visibility

Supervisors gained instant access to task progress, deviation status, and aircraft service history, enabling better decision-making and resource planning during scheduled and unscheduled maintenance.

68%Boost in functional efficiency

82%Increase in staff collaboration

71%Better customer support

45%Faster and precise decision making

Our Process to Turn Ideas Into Scalable Digital Products

01.Discovery & Insights

- Business Objectives

- Audience Research

- Competitor Benchmarking

- Journey Mapping

- Technical Feasibility

02.Concept & Planning

- Site Structure

- UI Moodboards

- User Scenarios

- Feature Prioritisation

- Solution Mapping

03.Visual Design & UX

- Style Guides

- Wireframes

- High-Fidelity Mockups

- Interactive Clickable Prototypes

04.Engineering & Build

- Frontend Development

- Backend Architecture

- Secure API Integrations

- Scalable Codebase

05.Testing & Launch

- QA & Performance Checks

- Device Compatibility

- App Store Deployment

- Launch Support & Iteration

- Ongoing Maintenance